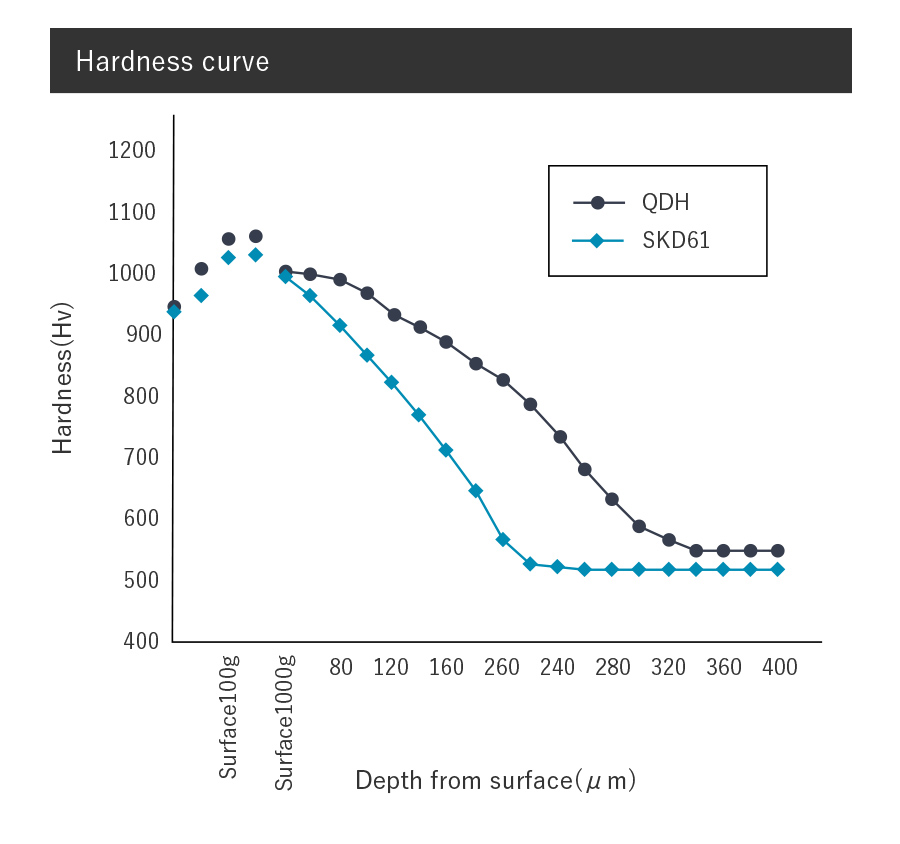

The effective temperature range of nitriding treatment is limited to 800°C.

The cause is decomposition of nitride at high temperature ➡ Decrease in nitride hardness due to evaporation. In addition, repeated rapid heating ➡ rapid cooling cause early cracks, progressive fractures, and large cracks.

Therefore, a white ceramic layer is used as a barrier on the surface of the mold to create a “Flexible & Tough coating” that is resistant to rapid heating ➡ rapid cooling.

For die-casting dies used in the temperature range of around 700°C, it is thought that the white layer on the outermost surface causes initial cracks due to the cycle time of repeating heating ➡ cooling.

As an effective countermeasure against the occurrence of cracks, these initial cracks can be delayed by making the white layer, which is sensitive to rapid heating and cooling, as thin as possible.

In addition, there is the idea of reducing the nitriding depth with a gentle hardness gradient in the range of 50 to 100 μm so that the heat cracks do not progress too deeply. However, at high temperatures of 900°C or higher, the current situation is that production is not possible unless the mold contact temperature is high and the protective function of the glass-based coating agent can be effectively utilized. Therefore, it is required to improve the retention of the glass-based coating agent and develop a coating that protects from heat shock. The completed solution is the “strong white layer.”

This strong and flexible white layer is a nitriding method that makes full use of hard and soft elements of surface treatments, rather than being chemically manufactured.

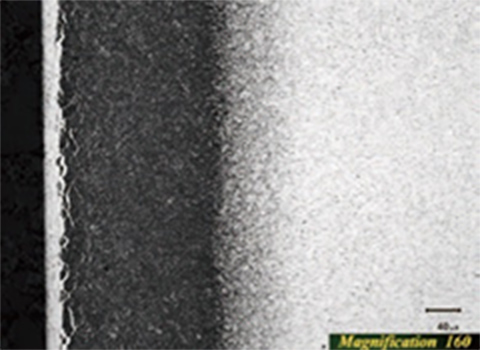

(SKD61) × 160

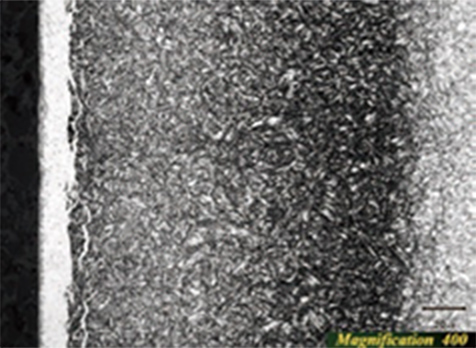

(SKD61) × 400

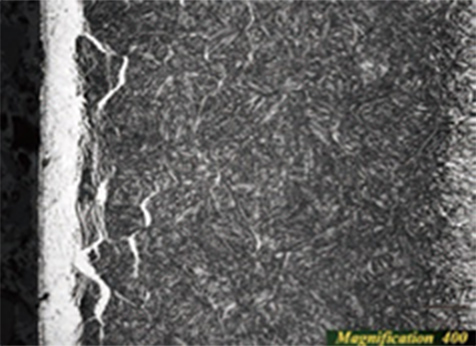

(DH31) × 400

The film quality was verified by driving an indenter directly above the nitrided surface using a Rockwell hardness tester and observing the cracks generated in the indentation.

This is the result of conducting the HRC (150kgf) test.

51.0HRC (+0.5)

51.0HRC (+0.5)